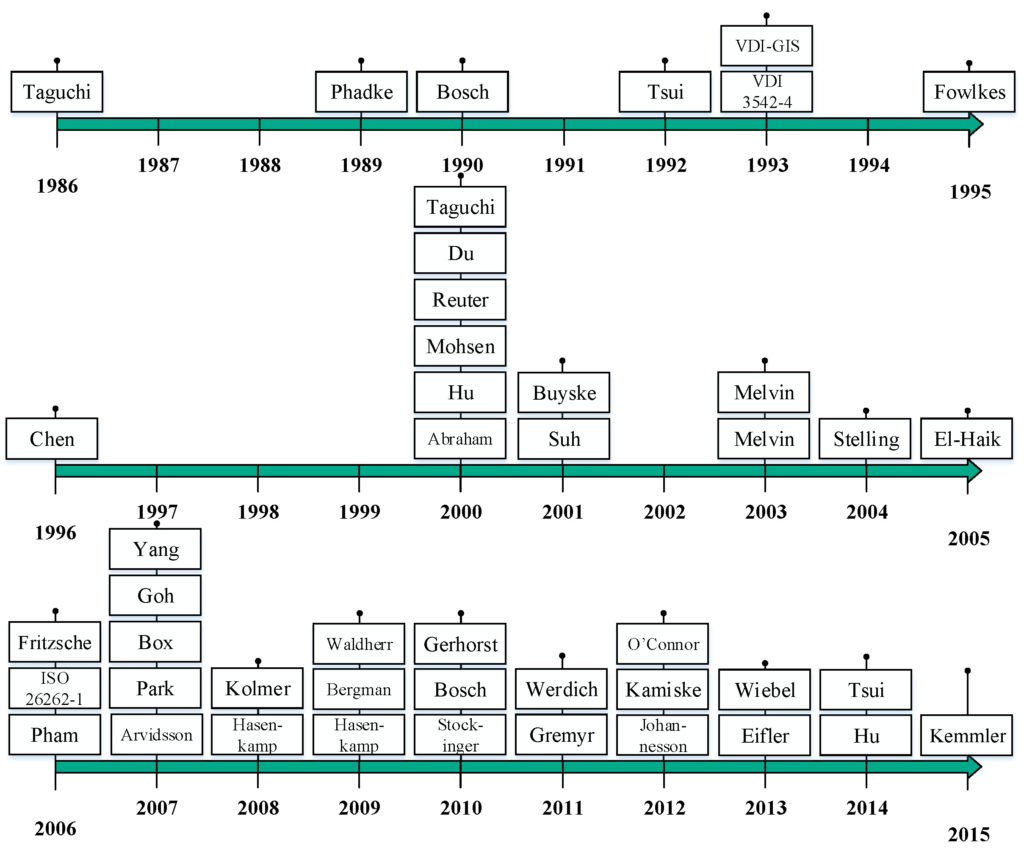

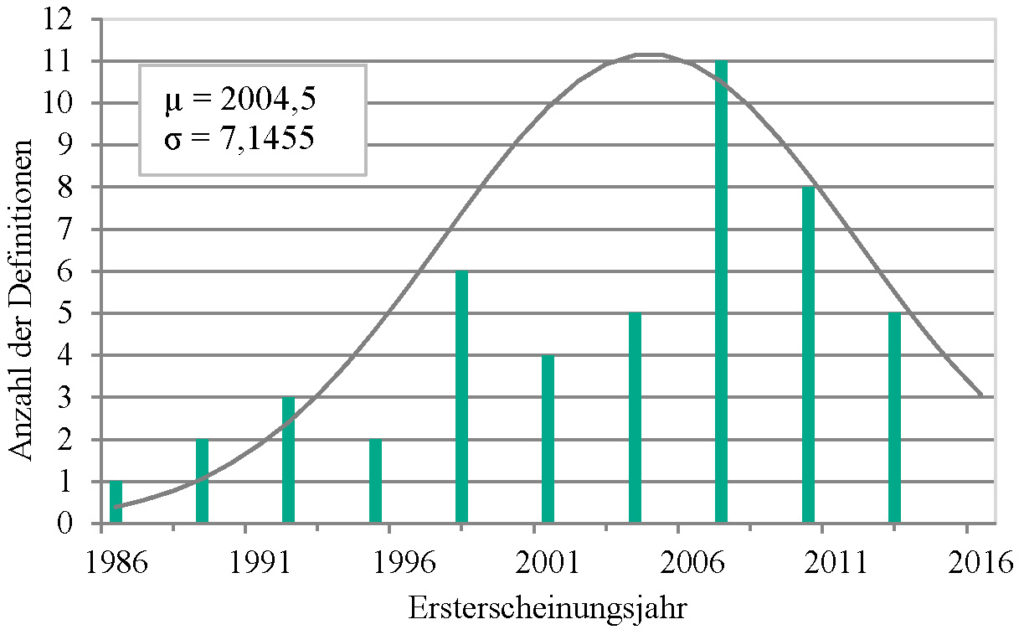

On this page, the definitions of Robustness and Robust Design, which can be found in the literature, are listed, see Table 1.1.1. Since the existing number of definitions exceeds the scope of the work, only a direct description of the term “Robustness” or the related adjective “robust” is treated as a definition. In addition, a description of Robust Design or the Robust Design methodology is valid as a valid hit. A summary of all definitions with regard to their year of appearance is given in Figure 1.1.1. A frequency distribution is shown in Figure 1.1.2.

Bild 1.1.1: Chronological defintion overview

Bild 1.1.2: Frequency distribution of the Robust Design definitions

The chronological listing of the sources after their first publication shows that the first definition from the book “Introduction to Quality Engineering: Designing Quality into Products and Processes” by the Japanese engineer Taguchi from 1986. The most recent definition was published in 2015 by Stefan Kemmler in the paper “Comparison of Taguchi Method and Robust Design Optimization (RDO)”. The result of the time observation shows that the number of definitions for the term Robustness / Robust Design with a number of over 40 hits is very high in the literature. Furthermore, at least one new definition is published almost once a year during the period under review. This indicates that robustness has been a relevant topic in mechanical engineering for more than 30 years.

Tabelle 1.1.1: Definitions of the term Robustness / Robust Design – Quelle: Kemmler, Dissertation 2018

| Autor | Definition(en) | Quelle |

|---|---|---|

| Arvidsson | „Robust Design Methodology means systematic efforts to achieve insensitivity to noise factors. These efforts are based on an awareness of variation and are applicable in all stages of product design.“ „Through this review four central principles of robust design areidentified: awareness of variation, insensitivity to noise factors, application of various methods, and application in all stages of a design process.“ | [1] |

| Arvidsson | „We characterize Robust Design Methodology by three principles: awareness of variation, insensitivity to noise factors, and continuous applicability.“ „Robust design...has been developed to improve the quality and reliability of the product in engineering.“ | [2] |

| Abraham | „This is a special experimental arrangement in which the opportunity is provided to find controllable factors which can be used to reduce variation induced by the noise factors.“ | [3] |

| Bergmann | „Robust Design Methodology is a systematic search for design solutions insensitive to variation in usage, manufacturing and deterioration of products as well as to varying system environments.“ „Robust Design Methodology means systematic efforts to achieve insensitivity to noise factors. These efforts are founded on an awareness of variation and can be applied in all stages of product design.“ | [4] |

| Bosch | „Robust Design ist, wenn ein Produkt/Prozess eine gleichmäßig hohe Qualität liefert, trotz bestehender Abweichungen und Streuungen.“ | [5] |

| Bosch | „Robustheit = Fähigkeit einer Betrachtungseinheit, auch bei Verletzung der spezifizierten Randbedingungen vereinbarte Funktion zu erfüllen bzw. ihre Funktionsfähigkeit zu erhalten“ | [6] |

| Box | „...minimizing sensitivity by appropriate choice specifications“ „Robustness means insensitiviry to variation.“ | [7] |

| Buyske | „Robust Design is a technique that reduces variation in a product by reducing the sensitivity of the design of the product to sources of variation rather than by controlling their sources.“ „The end result is a robust design, a design that has minimum sensitivity to variations in uncontrollable factors. “ | [8] |

| Chen | „The fundamental principle in robust design is to improve the quality of a product by minimizing the effects of variation without eliminating these causes.“ | [9] |

| Du | „if the system output is considered as the constraint“ | [10] |

| Eifler | „Initially RDM was centered on the concept of quantifying the societal loss due to variation in functional performance and on the use of experimental analysis to select values of design parameters, such that the resulting design became insensitive to changes in the design parameters.“ | [11] |

| El-Haik | „Robustness means that a design solution entity delivers its intended functional requirements under all operating conditions (different causes of variation) throughout its intended life.“ | [12] |

| Fowlkes | „Robust Design is a disciplined engineering process that seeks to find the best expression of a product design. "Bestïs carefully defined to mean that the esign is the lowest-cost solution to the product design specification, which is based on the customer needs.“ | [13] |

| Fritzsche | „Unter Robustheit ist die Differenz zwischen der Belastung auf das Produkt und die Belastbarkeit zu verstehen. Einfach ausgedrückt kann die Robustheit auch als Abstand zur Fehlermöglichkeit beschrieben werden.“ | [14] |

| Gerhorst | „The main aspect of the optimization process to be discussed here will be stratified part load robustness which means misfire-free and smooth operation with a low level of cyclic fluctuations.“ | [15] |

| Goh | „Robust design succeeded in expanding the horizon of industrial experimentation in two significant ways: 1. The application of design of experiments takes place much earlier, from the fine-tuning of existing physical systems to the optimization of new products or processes at their design stage: This would avoid costly changes due to quality problems that are realized after production is already in full swing. 2. By way of including, usually by simulation, potential noise factors in the experiments, designs can be suitably adjusted beforehand to counteract the impact of anticipated noise both during manufacturing and throughout the product life: this extends the contribution of design of experiments from a static quality focus to the realm of reliability engineering.“ | [16] |

| Gremyr | „methodology for gaining time, reducing costs and winning quality“ „a means to achieve insensitivity to variation and that further facilitates the listing of important factors in early phases of product development.“ „. . . to deliver customer expectations at a profitable cost, regardless of: customer usage, manufacturing variation, supplier variation, distribution, delivery and installation variation and degradation over product life.“ „To the company, RDM means delivering customer expectations at a profitable cost, regardless of customer usage, manufacturing variation, supplier variation, distribution, delivery and installation variation and degradation over the product’s life.“ | [17] |

| Hasenkamp | „The basic techniques and tools to be used for this during late stages of the development process are since quite long well known and its systematic usage is often called Robust Design Methodology or, in Japan, Quality Engineering.“ „Here, a robust design constitutes a product that performs on target despite presence of noise factors, and consequently Robust Design Methodology (RDM) could be defined as a methodology for designing products in a way that makes their performance insensitive to noise factors.“ „RDM can be described as a means of designing products in a way that makes their performance insensitive to noise factors.“ | [18] |

| Hasenkamp | „Robust design methodology (RDM) comprises systematic efforts to achieve insensitivity of products or processes to sources of unwanted variation.“ | [19] |

| Hu | „Within a given structure or design, how an engineered system can be optimized to desensitize the side effects of uncontrollable conditions.“ | [20] |

| Hu | „Robust design, also known as Taguchi parameter design, can be used to achieve robust reliability; that is, to make a product’s reliability insensitive to uncontrollable user environments.“ „The ability to transform input to output as closely to ideal function as possible in the presence of uncontrollable user environment.“ | [21] |

| ISO 26262-1 | „design that has the ability to function correctly in the presence of invalid inputs or stressful environmental conditions.“ „for software, robustness is the ability to respond to abnormal inputs and conditions“ „for hardware, robustness is the ability to be immune to environmental stress and stable over the service life within design limits“ „in the context of ISO 26262, robustness is the ability to provide safe behaviour at boundaries“ | [22] |

| Johannesson | „Making the design insensitive to unavoidable variation is called robust design and is handled by (i) identification and classification of variation, (ii) design of experiments to find robust solutions, and (iii) statistically based estimations of proper safety margins.“ | [23] |

| Kamiske | „Ein Produkt ist robust, wenn die gewünschte Funktionalität und Performance des Produkts unabhängig von der Variation der Rohmaterialien, der Streuung des Herstellungsprozesses und den unterschiedlichen Betriebsbedingungen des Produkts ist.“ „Robustheit ist die Fähigkeit eines Produkts/Systems, seine Funktion auch bei Schwankungen der Umgebungsbedingungen aufrechtzuerhalten“ | [24] |

| Kemmler | „One approach to designing such products is the Robust Design Method (RDM), whose aim is to create products insensitive to uncontrollable variations (noise factors).“ | [25] |

| Kitano | „An ability of the system to maintain its functions even under external and internal perturbations.“ | [26] |

| Kolmer | „Fähigkeit eines Systems, seine Funktion auch bei Schwankungen der Umgebungsbedingungen aufrecht zu erhalten.“ | [27] |

| Melvin | „The premise of robust design is that product variance is caused by noise factors, which may come from many places, throughout the life of the product, and through experimentation it is possible to make the product and production process less sensitive to sources of variation, so it may always achieve its desired purpose.“ | [28] |

| MIT | „A Robust Product or Processperforms correctly, even in the presence of noise factors.“ | [29] |

| Mohsen | „A robust system is expected to perform its intended function under all operating conditions (different causes of variations) throughout its intended life without necessarily eliminating noise factors (noise factors are defined as disturbance factors that cause system functional variability).“ | [30] |

| O’Connor | „An important reliability feature of software system design is robustness, the term used to describe the capability of a program to withstand error conditions without serious effect, such as becoming locked in a loop or ‘crashing’.“ | [31] |

| Park | „In robust design, quality improvement is attained by minimizing the change of product performance when there are tolerances on design variables or unknown environmental perturbation.“ | [32] |

| Phadke | „Robust Design is an engineering methodology for improving productivity during research and development so that high-quality products can be produced quickly and at low cost.“ | [33] |

| Pham | „Robust design is a systematic methodology that uses statistical experimental design to improve the design of products and processes.“ | [34] |

| Reuter | „Robustness means finding an acceptable balance between the scatter of the input (=system parameters) and the scatter of the performance.“ | [35] |

| Stelling | „In general, robustness means the persistence of a system’s characteristic behavior under perturbations or conditions of uncertainity.“ | [36] |

| Stockinger | „Robust Design ist eine Methode zur optimalen Auslegung von Produkten und Prozessen, so dass sie unempfindlich gegen über Variationen von Eingangsgrößen und Randbedingungen sind. Die Methodik wird eingesetzt, um die Qualität von Produkten und Prozessen zu steigern.“ | [37] |

| Suh | „Robust design is defined as the design that satisfies the functional requirements even though the design parameters and the process variables have large tolerances for ease of manufacturing and assembly. This definition of robust design states that the information content is minimized.“ „a design that can always satisfy the functional requirements (i.e. 100% of the time) by tolerating large variation in design parameters and process variables.“ | [38] |

| Taguchi | „Robustness is the state where the technology, product, or process performance is minimally sensitive to factors causing variability (either in the manufacturing or the user’s environment) and aging at the lowest unit manufacturing cost.“ | [39] |

| Taguchi | „a product whose performance is minimally sensitive to factors causing variability (at the lowest possible cost)“ | [40] |

| Tsui | „Robust design is an important method for improving product quality, manufacturability and reliability at low cost. The main idea of robust design is to reduce the output variation from the target (the desired output) by making the performance insensitive to noise factors such as manufacturing imperfections, environmental variations and deterioration.“ | [41] |

| Tsui | Robust design is an efficient and systematic methodology that applies statistical experimental design for improving product and manufacturing process design.“ | [42] |

| VDI 3542-4 | „Robustheit meint demgegenüber, dass ein System Bedienfehler verzeiht und gegenüber Abweichungen von den spezifizierten Betriebsbedingungen weitgehend unempfindlich ist.“ | [43] |

| VDI-GIS | „Fähigkeit eines Objekts, auch bei Verletzung der spezifizierten Randbedingungen vereinbarte Funktionen zu erfüllen bzw. seine Funktionsfähigkeit zu erhalten.“ | [44] |

| Waldherr | „A robustness measure is defined by the extent of parametric uncertainty for which no local bifurcations occur.“ | [45] |

| Werdich | „Unter robustem Design wird ein Design verstanden, welches gegen Schwankungen von Störgrößen (z. B. Toleranzüberschreitungen einzelner Merkmale) unempfindlich reagiert, d. h. die geforderten und erwarteten Funktionen auch dann nachweislich erfüllt.“ | [46] |

| Wiebel | „Ein Produkt wird als robust bezeichnet, wenn es sich unempfindlich gegenüber den auftretenden Unsicherheiten seiner Lebenslaufprozesse verhält.“ | [47] |

| Will | „Die Robustheit charakterisiert dabei die Empfindlichkeit der Systemantworten gegenüber unvermeidlichen, in Natura vorhandenen Streuungen in den Umweltbedingungen, übertragen auf die Inputvariablen der rechnerischen Simulation.“ | [48] |

| Yang | „Robust design is a powerful technique for improving reliability at low cost in a short time. Robust design is a statistical engineering methodology for optimizing product or process conditions so that product performance is minimally sensitive to various sources of variation.“ „Robustness of a diagnostic system is the capability of the system to detect the true states of the prime system consistently in the presence of noise sources.“ | [49] |

| Quellen: | ||

| [1] | ARVIDSSON, M. ; GREMYR, I. ; HASENKAMP, T. : An operationalization of Robust Design Methodology | |

| [2] | ARVIDSSON, M. ; GREMYR, I. : Principles of Robust Design Methodology. In: www.interscience.wiley.com (2007) | |

| [3] | ABRAHAM, B. ; BRAJAC, M. : Variation Reduction and Robust Designs. In: Taylor & Francis Group (2000) | |

| [4] | BERGMAN, B. ; MARÉ, J. de ; LORÉN, S. ; SVENSSON, T. : Robust Design Methodology for Reliability. John Wiley & Sons, 2009 | |

| [5] | BOSCH: Robust Design als Design for Six Sigma Baustein bei der Robert Bosch GmbH. In: www.dynardo.de/library (2010) | |

| [6] | N.N.: Qualitätssicherung der Bosch-Gruppe Nr. 1-12. In: Robert Bosch GmbH (1990) | |

| [7] | BOX, G. ; FUNG, C. A.: Quality Quandaries- Is your Robust Design Procedure Robust? In: Taylor & Francis Group (2007) | |

| [8] | BUYSKE, S. ; TROUT, R. : Robust Design and Taguchi Methods. In: Rutgers (2001) | |

| [9] | CHEN,W. ; ALLEN, J. K. ; TSUI, K.-L. ; MISTREE, F. : A Procedure for Robust Design: Minimizing Variations Caused by Noise Factors and Control Factors. | |

| [10] | DU, X. ; CHEN, W. : A most probable point based method for uncertainity analysis. In: Design Engineering Technical Conferences (2000) | |

| [11] | EIFLER, T. ; EBRO, M. ; HOWARD, T. J.: A classification of the industrial relevance of Robust Design Methods. In: International Conference on Engineering Design (2013) | |

| [12] | EL-HAIK, B. S.: Axiomatic Quality. John Wiley & Sons, 2005 | |

| [13] | FOWLKES, W. Y. ; CREVELING, C. M.: Engineering Methods for Robust Product Design. Addison-Wesley Publishing Company, 1995 | |

| [14] | FRITZSCHE, R. : Erstellung von Parameter-Diagrammen in der Automobilindustrie. Automobiltechnische Zeitschrift (ATZ), 2006 | |

| [15] | GERHORST, F. ;WIRTH, M. ; KUHLBACH, K. : Application of Monte-Carlo-Simulation and Most Probable Limit State on Gasoline DI Combustion System Optimization. In: SAE International (2010) | |

| [16] | GOH, T. N.: The Role of Statistical Design of Experiments in Six Sigma: Perspectives of a Practitioner. In: Taylor & Francis Group (2007) | |

| [17] | GREMYR, I. ; HASENKAMP, T. : Practices of robust design methodology in practice. In: The TQM Journal (2011) | |

| [18] | HASENKAMP, T. : Designing for Robustness. Chalmers University of Technology, 2009 | |

| [19] | HASENKAMP, T. ; ARVIDSSON, M. ; GREMYR, I. : A review of practices for Robust Design Methodology. In: Taylor & Francis Group (2008) | |

| [20] | HU, M. : Robustness Thinking in Design for Reliability. In: AR&MS (2014) | |

| [21] | HU, M. ; YANG, K. ; TAGUCHI, S. : Enhancing Robust Design with the Aid of TRIZ and Axiomatic Design (Part I). In: TRIZ Journal (2000) | |

| [22] | ISO 26262-1: Road vehicles- Functional safety- Part 1: Vocabulary / ISO. 2011. | |

| [23] | JOHANNESSON, P. ; BERGMAN, B. ; SVENSSON, T. ; ARVIDSSON, M. ; LÖNNQVIST, A. ; BARONE, S. ; MARÉ, J. de: A Robustness Approach to Reliability. In: Quality and Reliability Engineering International (2012) | |

| [24] | KAMISKE, G. F.: Handbuch QM-Methoden: Die richtige Methode auswählen und erfolgreich umsetzen. 2. Carl Hanser Verlag GmbH & Co. KG, 2013 | |

| [25] | KEMMLER, S. ; FUCHS, A. ; LEOPOLD, T. ; BERTSCHE, B. : Comparison of Taguchi Method and Robust Design Optimization (RDO). In: Weimar Optimization and Stochastic Days (2015) | |

| [26] | KITANO, H. : System Drug Design. In: The Systems Biology Institute | |

| [27] | KOLMER, A. : Robuist Design- Robustheitsmaße. In: Fraunhofer (2008) | |

| [28] | MELVIN, J. W.: Axiomatic System Design: Chemical Mechanical Polishing Machine Case Study, Massachusetts Institute of Technology, Diss., 2003 | |

| [29] | MIT: Robust Design: Experiments for Better Products. In: MIT | |

| [30] | MOHSEN, H. A. ; CEKECEK, E. : Thopughts ion the use of Axiomatic Design with the product development process. In: First International Conference on Axiomatic Design (2000) | |

| [31] | O’CONNOR, P. : Practical Reliability Engineering. John Wiley & Sons, 2012 | |

| [32] | PARK, G.-J. : Analytic Methods for Design Practice. Springer-Verlag GmbH, 2007 | |

| [33] | PHADKE, M. S.: Quality Engineering using Robust Design. AT&T Bell Laboratories, 1989 | |

| [34] | PHAM, H. : Springer Handbook of Engineering Statistics. Springer-Verlag GmbH, 2006 | |

| [35] | REUTER, R. ; HÜLSMANN, J. : Achieving design targets through stochastic simulation. In: Madymo’s User’s Conference (2000) | |

| [36] | STELLING, J. ; SAUER, U. ; SZALLASI, Z. ; DOYLE, F. J. ; DOYLE, J. : Robustness of Cellular Functions. In: Max Planck Institute for Dynamics of Complex Technical Systems (2004) | |

| [37] | STOCKINGER, A. : Computer Aided Robust Design- Verknüpfung rechnerunterstützer Entwicklung und virtuelle Fertigung als Baustein des Toleranzmanagements, Universität Erlangen-Nürnberg, Diss., 2010 | |

| [38] | SUH, N. P.: Axiomatic Design: Advances and Applications. Oxford University Press, 2001 | |

| [39] | TAGUCHI, G. : Introduction to Quality Engineering: Designing Quality into Products and Processes. Asian Productivity Organization, 1986 | |

| [40] | TAGUCHI, G. ; CHOWDHURY, S. ; TAGUCHI, S. : Robust Engineering. American Supplier Institute, 2000 | |

| [41] | TSUI, K.-L. : A critical look at Taguchi’s modelling approach for robust design. In: Taylor & Francis (2014) | |

| [42] | TSUI, K.-L. : An overview of Taguchi method and newly developed statistical methods for robust design. In: IIE Transactions (1992) | |

| [43] | Sicherheitstechnische Begriffe für Automatisierungssysteme Zuverlässigkeit und Sicherheit komplexer Systeme (Begriffe) / Verein Deutscher Ingenieure. 2000. | |

| [44] | Software-Zuverlässigkeit – Grundlagen, konstruktive Maßnahmen, Nachweisverfahren. In: Verein Deutscher Ingenieure (1993) | |

| [45] | WALDHERR, S. : Uncertainty and robustness analysis of biochemical reaction networks via convex optimisation and robust control theory, Universität Stuttgart, Diss., 2009 | |

| [46] | WERDICH, M. : FMEA-Einführung und Moderation: durch systematische Entwicklung zur übersichtlichen Risikominimierung (inkl. Methoden im Umfeld). Springer-Verlag GmbH, 2011 | |

| [47] | WIEBEL, M. ; EIFLER, T. ; MATHIAS, J. ; KLOBERDANZ, H. ; A., B. ; BIRKHOFER, H. : Modellierung von Unsicherheit in der Produktentwicklung. Springer Fachmedien Wiesbaden. | |

| [48] | WILL, J. ; ROSS, D. ; RIEDEL, J. : Robustheitsbewertung in der stochastischen Strukturmechanik. In: Dynardo GmbH (2003) | |

| [49] | YANG, G. : Life Cycle Reliability Engineering. John Wiley & Sons, 2007 | |

Deutsch

Deutsch