Robust Design (RD) has evolved into a variety of research fields over time, including Robust Design Methods, Robust Parameter Optimization etc. [1, 2] Nevertheless, the basic principles mostly originate from the work of the Japanese engineer and statistician Genichi Taguchi in the late 1950’s [3]. To extract the essence of Robustness and to clarify the overall objective of Robust Design, they are still the most relevant.

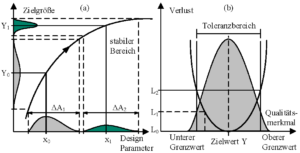

Fundamentally, Robustness describes the insensitivity of products or processes against different sources of variation, such as production or assembly tolerances, not (fully) specified load scenarios or ambient use conditions [3, 2]. Whereas traditionally accommodated by quality control measures, safety factors, etc., i. e. additional costs or inefficiencies built into products, RD consequently aims at the development of products or processes which function as intended in spite of this variation [4]. The underlying, essential assumption of RD theory is best illustrated by means of the Quality Loss Function. Traditional quality control methods interpret all products within specification limits (SL) as equally good. In contrast, RD is based on the awareness that even small variations of the required product performance can lead to a loss of the customer’s quality perception [3, 1], see in Figure 1 (b).

Figure 1: Relevance of variation described as (a) Transfer and the (b) Quality Loss function

The aim of Robust Design is consequently to minimize the variation of the relevant product performance which is usually influenced by a large number of different factors. Figure 1 (a) illustrates this dependency simplified to one single design parameters (DP). The gradient of the shown so-called Transfer Function represents the product’s sensitivity towards the variation of the input parameter , in other words the Robustness [3, 2]. The steeper the gradient is, the higher the resulting variation of the performance will be. The design of robust products or processes relates consequently to an intended and systematic manipulation of the transfer function’s gradient. Please see the summary of Eifler et al. [1] for an overview about the variety of corresponding methods available nowadays.

____________

[1] Eifler, T., Ebro, M., Howard, T.J.: A classification of the industrial relevance of Robust Design methods. Proc. International Conference on Engineering Design – ICED, 19. – 22. August, 2013, Seoul / South Korea.

[2] Jugulum, R. Frey, D. D.: Toward a taxonomy of concept designs for improved robustness. Journal of Engineering Design, 18, No. 2, 2007, pp. 139–156.

[3] Taguchi, G. et al.: Taguchi’s Quality Engineering Handbook. New Jersey: John Wiley & Sons, Inc. 2005.

[4] Ebro, M., Howard, T.J. and Rassmussen, J.J.: The Foundation of Robust Design. Proc. International Design Conference – DESIGN, 2012, Dubrovnik/Croatia.

Deutsch

Deutsch